What are the secrets of biosafety in European pig farms? Creciente Gao Song: Blocking pathogens and supplementing high-quality protein sources are two key points.

The policy of no resistance has been implemented for nearly a year. How can pig farms improve their biosafety level and production efficiency? On May 16th, 2021, Gao Song, the technical director of Xiamen Creciente Agritech Co., Ltd., shared the experience of improving the biosafety of pig farms in the era of European anti-resistance.

The secret of biological safety in European pig farms: strict and meticulous

Biosafety includes two aspects: one is to prevent the introduction of new diseases from the outside to the inside; The second is to control the spread of existing diseases in the field from the inside out. Gao Song introduced that there are four main principles for the biosafety of pig farms: 1. Separate infected pigs from healthy pigs; 2. Reduce the overall infection pressure; 3. Break the infection cycle; 4. Reduce the pressure on the immune system.

Gao Song summarized some biological safety measures outside the pig farm, such as establishing an entrance disinfection pool, shower room and hand washing pool. Before entering the pig farm, people should take a bath or wash their hands, and use hand sanitizer and hand disinfectant with disinfection function. Replace isolation suits and sterilized boots after bathing, and establish vehicle disinfection facilities, foreign animal barrier facilities, and dead pig temporary storage facilities.

Internal biological safety includes three aspects, namely, disease control, working lines and equipment, cleaning and disinfection. Gao Song believes that the breeding density has a great influence on the incidence frequency, and the working order of pig farms is from small pigs to big pigs. Special equipment, clothing and shoes and boots in each area should be distinguished by different colors.

Gao Song introduced that the standard cleaning and disinfection process can be divided into six steps: cleaning and dust removal → wetting → cleaning+soaking → contact for 30-60 minutes → washing and drying → disinfection. When cleaning, it is not enough to wash the pig farm with a high-pressure water gun. Gao Song explained that the cleaning process requires the use of detergents. Biofilm is an ideal shelter for bacteria and viruses, but water and disinfectant can't penetrate the biofilm, which affects the disinfection effect. Therefore, in order to penetrate the biofilm, enough surfactants are needed.

The experimental results of disinfection in fattening piggery show that the total number of bacteria in dirty piggery is about 50,000,000 CFU/cm2, which can be reduced by about 60% after washing with water, and by 90% after washing with detergent, and 99.9% of pathogens can be eliminated after disinfection.

Regarding sow cleaning, Gao Song suggested that sow sterilization bath lotion can be used, which has strong cleaning effect, can effectively sterilize and improve skin condition, is convenient to use and smells fragrant, and can effectively break the disease cycle and solve the problems of staphylococcus and streptococcus.

The cleanliness of water and waterline is very important.

Water is the most important nutrition for pigs. A piglet under 27kg needs about 2.8L of drinking water every day, and a nursing sow needs as much as 10-30L of water every day. Therefore, it is particularly important to provide clean drinking water for pigs in the biosafety defense line, and pig farms must pay attention to the cleanliness of water and waterline.

In daily production, biofilm will pollute water quality. Gao Song compared the removal effects of different products on biofilm. It can be seen that formic acid can not effectively remove biofilm, hydrogen peroxide has a bad effect on removing calcium carbonate, and soft acid can not only effectively clean biofilm but also clean calcium carbonate. Therefore, adding soft acid to feed raw materials, water and feed in farms has a long-term inhibitory effect on biofilm and pathogens, which is helpful to clean the waterline, remove microorganisms and biofilm, and is very gentle.

Soft acid can meet the requirements of bacteriostasis, synergism, cleaning and so on.

Under the background of antibiotices in feed ban, the industry is looking for high-quality antibiotic substitutes. At present, there are mainly small molecular organic acids, plant essential oils and other products on the market

Due to the characteristics of small molecular organic acids, such as strong irritation (poor palatability, low intake), strong corrosiveness (damaging equipment, harmful to human health) and strong volatility (increasing economic losses), the production technology of acidifiers is particularly important.

Gao Song introduced that soft acid is a mixed product of lignosulfonic acid and different small molecular organic acids by Norwegian Borregaard Company, which alleviates the corrosiveness of organic acids, hence the name "soft acid".

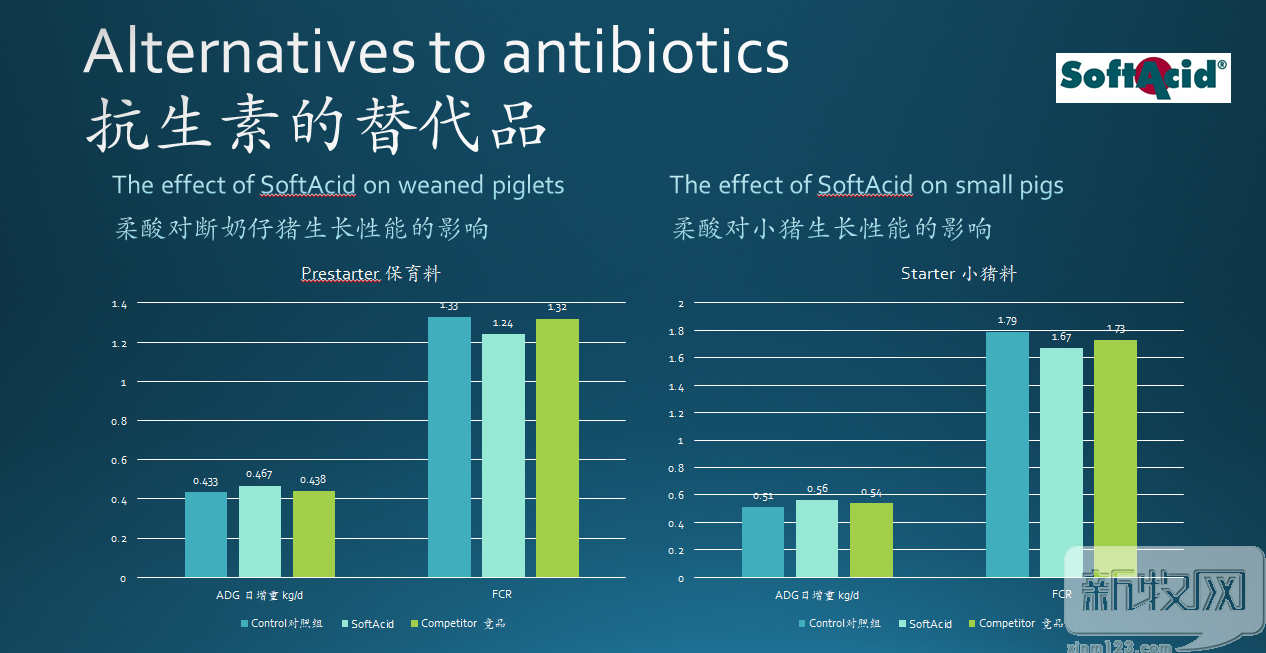

Soft acid has various functions, and lignosulfonic acid has strong inhibitory properties on bacteria and mold. Through experiments, it was found that adding soft acid to feed can effectively increase the daily gain of weaned piglets and reduce the feed-meat ratio. In addition, soft acid can also reduce the sedimentation of liquid feed, which is suitable for liquid feeding and helps non-resistant culture.

High-quality protein source can improve the immunity and growth performance of pigs

During the prevention and control of COVID-19 epidemic, Professor Zhong Nanshan and Professor Zhang Wenhong said that they needed to supplement enough milk and eggs every day to enhance their resistance. By the same token, when fighting diseases in pig farms, we can also improve the nutritional level of animals through high-quality protein sources, thus improving the disease resistance of pigs.

According to Gao Song, fish peptide, concentrated whey protein, piglet milk replacer and so on are all high-quality protein sources. The data from Sterksel experimental pig farm of Wageningen University and Research Center in the Netherlands show that fish peptide is beneficial to digestion and absorption, and the feed intake of lactating sows and the daily gain of suckling piglets have increased significantly after feeding "Yutaitai".

Over the past decade, the production achievements of pig farms at home and abroad, such as the number of live litters and weaning, the number of live litters and weaning per year of sows, have been constantly improving, and the contradiction between the increase of litter size and the lack of milk for piglets has become increasingly prominent.

In order to obtain better production benefits, piglets must be supplemented with adequate nutrition. Gao Song introduced that milk replacer can stimulate piglets to eat and reduce weaning stress. The results of experiments in many pig farms in Spain showed that the mortality rate of piglets before weaning was significantly reduced and the weaning weight was significantly improved after feeding the milk substitute "Porcomel". The data of Sterksel pig farm in Wageningen, the Netherlands also showed that the weight of piglets fed with milk substitute "Porcomel" was about 1.12KG higher than that of the control group at 61 days. Therefore, Gao Song suggested that pig farms need to pay more attention to supplementing high-quality protein sources and piglet nutrition.